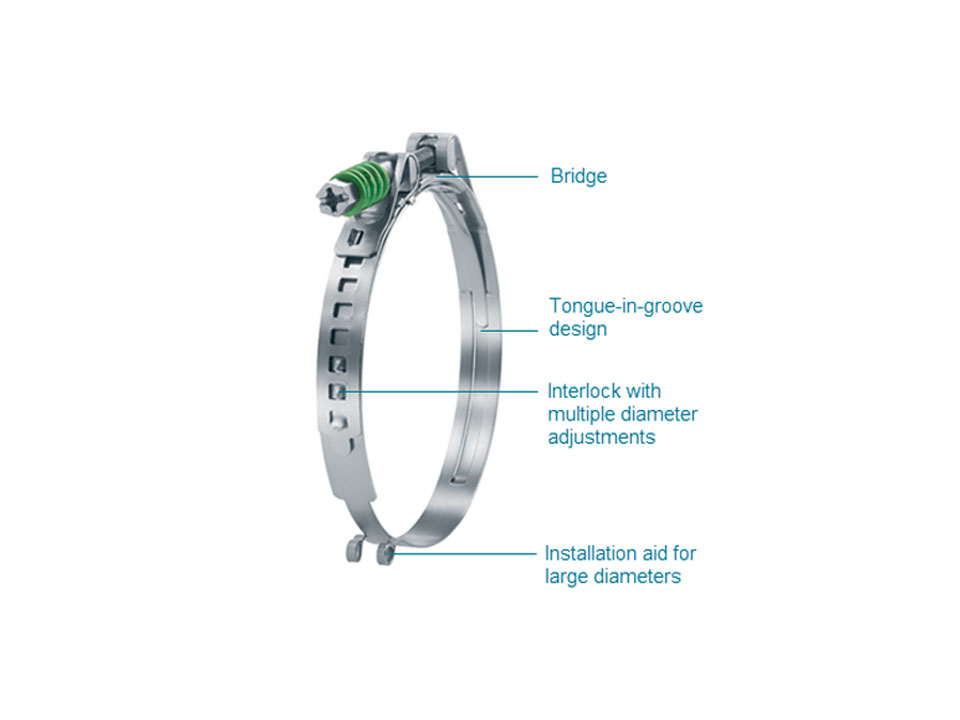

StepLess® Screw Clamp 178

Locking position options:

+ Clamp adjustable to very different nominal diameters

360° StepLess®:

+ Homogeneous compression and homogeneous surface pressure

Self-tensioning:

+ Thermal cycle balances diameter changes

Material

178 decks, spacers, retainers (D-nut)):

Stainless steel, material no. 1.4301 / UNS S30400

Screw: stainless steel, material no. 1.4319 / UNS S30200

Bow: 17-7PH (space industry quality)

Material Thickness

StepLess ® screw clamps and self-tensioned StepLess® screw clamps are made of 9 mm wide and 0.6 mm thick strip material. Strip sizes provide optimum sealing for EPDM rubber and silicone hoses, considering the required radial force, compressibility of the hose, sealing/insulating properties and environmental conditions.

Lock

The closure is a mechanical lock with the function of ensuring safe retention of the round clamp geometry. The lock can be opened to allow radial mounting of the clamp, while at the same time providing ease for the relocation of special parts of the lock, ensuring that alternate diameters are obtained prior to compression.

Positions by diameter differences

Dimensions 24-42 mm

- 3 different locations

- 1.6 mm diameter change at each stage

Dimensions 45-55 mm

- 3 different locations

- 2.1 mm diameter change at each stage

Dimensions 60-255 mm

- 5 different locations

- 2.0 mm diameter change at each stage

Screw: M4 x 0.7

Screw head: combination of cross socket and hex head screw

Assembly Proposals

1st. Turn the screw counterclockwise until it stops at the "D-nut".

2nd ed. Unlock for radial mounting or diameter change.

3. Place the open clamp around the hose. Place the tongue in the cavity and position the holes of the mechanical lock on the matching components. Lock the lock to the smallest possible extent.

4. Tighten the screw to the desired torque. Do not exceed the maximum allowable tightening torque.

5. There should be > 3 mm space between the D-nuts. This ensures that during contraction of the hose, when the self-tensioning clamp spring is elongated, the clamp can move sufficiently to reduce the diameter. If the gap between the D-nuts is less than the recommended 3 mm, proceed to step 6. (Self-Tensioned Spring Only

Applies to screw clamps).

6. Turn the screw counterclockwise to loosen the self-tensioning screw clamp.

7th ed. Place the lock on the next smaller anchor.

8. Tighten the screw to the desired torque. Do not exceed the maximum allowable tightening torque.

Tolerance balancing with StepLess® screw clamps

StepLess ® screw clamps and self-tensioned StepLess® screw clamps should be tightened with optimum torque as specified in the manual. For this torque, the degree of compression required, the radial force required, and the maximum torque resistance of the screw and clamp band are taken into account. With the use of a defined and constant torque for the assembly, it will always be possible to balance the component tolerances and the radial force will remain almost the same. The spring on the Oetiker self-tensioned StepLess ® screw clamps acts as a balancing element to adapt to changes in diameter due to thermal expansion and contraction or vibration. This feature gives screw clamps optimum sealing performance even in applications with strong thermal effects.

ONURFIX BÜLTEN ABONELİĞİ

Şirketimiz ile ilgili gelişmelerden haberdar olmak için bültenimize kaydınızı yaptırabilirsiniz.