StepLess® Low Profile Clamp 168 with Tolerance Compensation

Tolerance balancing: provides a degree of balancing according to component tolerances

Reusability: can be repeatedly disassembled and reassembled

360° StepLess®: 360° homogeneous compression and constant surface pressure

Low Height After installation: minimum space requirement, low imbalance in Rotary parts

Non-Burr slitting edges: less risk of damage to clamped parts

Material

168 stainless steel, material no. 1.4301 / UNS S30400 alternative materials on request.

During the selection of the clamp diameter, the dimensions of the matching components on which the clamp is to be mounted must be correctly determined to ensure effective clamping performance. In determining the appropriate clamp diameter, the durometer hardness of the soft material and the desired compression are important factors.

Stretching Crossings

By using an Oetiker tightening tool and applying it to the tensioning Gates, the diameter of the clamp is reduced until the load-holding hook settles into the gate and locks into the front edge. Although the reduction in clamp diameter is proportional to the closing distance, it can be affected by the lengthening of the tolerance balancing element in heavy loads.

Tolerance Balancing

Tolerance-balancing elements will act if the nominal diameter of the closed clamp cannot be achieved, due to the adjacent components being at the upper levels of the tolerance range. When the clamped parts have high durometer hardness values, the balancing element can be fully extended provided that the closed position can be achieved. For optimal performance, clamp diameter components should be selected based on lower theoretical tolerance limits. Then, when a group of larger dimensions is encountered, the tolerance balancing element lengthens to absorb the increased diameter and allow the load-bearing hook to lock in the tensioning passage. Application configuration, the physical properties of the sealed materials, and the desired insulation are critical factors in determining the overall functionality of the connection.

Assembly Proposals

These clamps are tightened manually by a specially developed hand tool or by using pneumatic pliers when higher pieces are to be mounted. To tighten the clamp, the ends of the pincer jaws must be passed to the tensioning pass at the end of the overlap and the pass next to the load-bearing hook. With the operation of the tightening tool, the clamp diameter is reduced to the position where the tightening hook locking occurs. The structure of the tolerance-balanced StepLess® low-profile clamps is such that when the correct position is achieved, the inner contour of the tensioner gate at the end of the overlap is automatically locked to the load-bearing hook. Without balancing tolerance StepLess® low-profile cuffs, unlike these small differences in component tolerances during assembly and balancing to adapt to thermal expansion and contraction due to changes in the cap element has the property to absorb. As with other types of clamp, the sealing pressure under the clamp is a factor of the diameters and materials of the components being compressed. The sealing properties of these clamps depend mainly on the opposing forces formed in the soft material of the fixed parts and on the preloading of the tolerance balancing element.

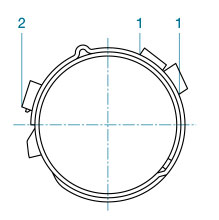

Rotation Diameter

The tolerance-balanced StepLess® low profile clamp has a low radial height and has been developed with the need to adapt to the tolerances of the connecting parts, especially for applications where space is limited.

Reusability

Tolerance-balanced StepLess ® low profile clamps can be reused to a limited extent. These can be repeatedly disassembled and reassembled – for example in the automotive industry, during periods of maintenance and service. These can be mounted both axially and radially. To open a clamp, the pliers must be attached to two passageways (1) and tightened. The applied force has the effect of slightly reducing the clamp diameter, allowing the hook to be released from the stretching passage (2) at the overlapping end.

Subscribe our Newsletter

You can register to our newsletter to be informed about developments about our company.